Wondering if a bad mass air flow (MAF) sensor can cause lean codes? Well, the answer is yes. A malfunctioning MAF sensor has the potential to trigger lean codes in your vehicle’s engine control module (ECM). When the MAF sensor fails to accurately measure the amount of air entering the engine, it can cause an imbalance in the air-fuel mixture, leading to a lean condition.

Lean codes typically indicate that there is too much air and not enough fuel in the combustion chamber. This can result in various issues such as rough idle, hesitation during acceleration, reduced power, and even engine misfires. Since the MAF sensor plays a crucial role in determining how much fuel should be injected into the engine based on incoming airflow data, any problems with its functionality can throw off this delicate balance.

If you’re experiencing lean codes on your vehicle’s ECM and suspect a faulty MAF sensor, it’s advisable to have it inspected and possibly replaced by a qualified mechanic. Remember that diagnosing automotive issues requires expertise and specialized tools. So, don’t hesitate to seek professional help for an accurate diagnosis and resolution of your lean code problem caused by a bad mass air flow sensor.

Can A Bad Mass Air Flow Sensor Cause Lean Codes

When it comes to diagnosing engine trouble, one common issue that arises is the presence of lean codes. But what exactly causes these lean codes to appear? Well, one possible culprit could be a bad mass air flow (MAF) sensor. Let’s delve into the world of lean codes and explore how a faulty MAF sensor can play a role in their occurrence.

Firstly, let’s understand what lean codes are. In simple terms, when an engine runs too lean, it means that there is an imbalance between the air and fuel mixture. This can lead to several problems, such as decreased power, rough idling, or even engine misfires. Lean codes usually indicate that there is too much air entering the combustion chamber relative to the amount of fuel being injected.

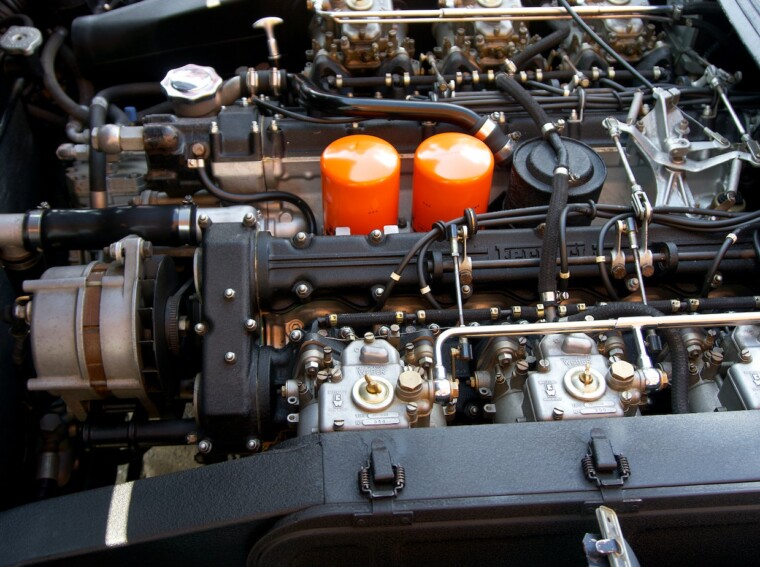

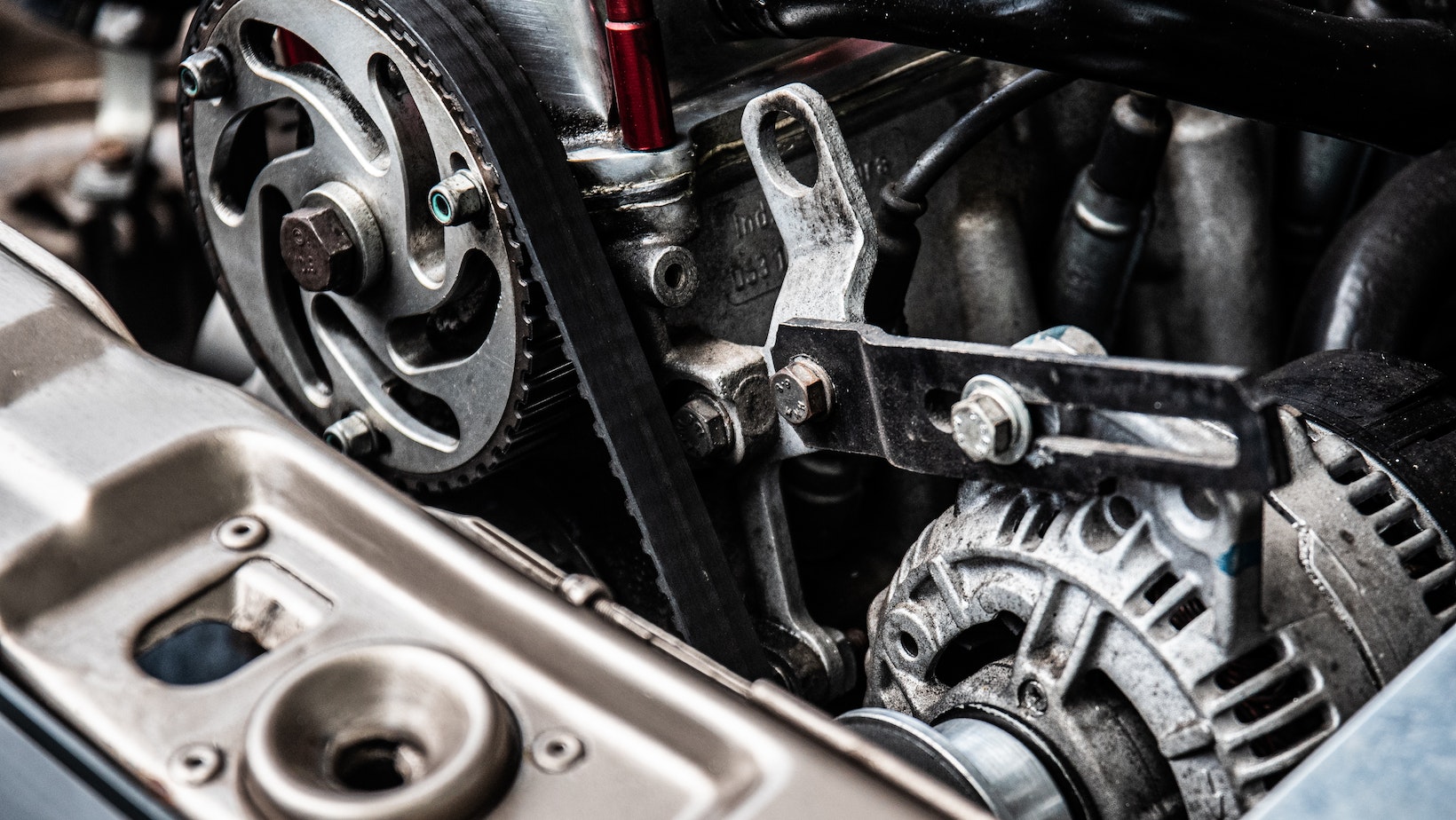

Now, let’s connect this to the MAF sensor. The MAF sensor measures the amount of incoming air flowing into the engine and sends this information to the engine control unit (ECU). The ECU then uses this data to calculate the appropriate amount of fuel to inject for optimal combustion. However, if the MAF sensor becomes faulty or contaminated with debris over time, it may not accurately measure the airflow.

When a bad MAF sensor fails to provide accurate readings, it can cause incorrect fuel delivery by providing inaccurate information to the ECU. As a result, the ECU might inject less fuel than necessary for proper combustion, leading to a lean condition in which there is insufficient fuel compared to airflow.

It’s important to note that while a bad MAF sensor can contribute to lean codes appearing in your vehicle’s diagnostic system, it isn’t necessarily always responsible for them. Other factors like vacuum leaks or malfunctioning oxygen sensors can also trigger lean conditions.

If you suspect that your vehicle has a bad mass air flow sensor causing lean codes, it’s recommended to consult with a qualified mechanic or use diagnostic tools specifically designed for this purpose. They will be able to perform tests on your MAF sensor and other relevant components to determine if they are functioning properly.

In conclusion, while there are various potential causes for lean codes in an engine diagnostic system; however, a bad mass air flow (MAF) sensor can indeed be one of them. When the MAF sensor fails to accurately measure the incoming airflow, it can result in an imbalance between air and fuel mixture, leading to a lean condition. If you suspect your MAF sensor is faulty, it’s best to consult with a qualified mechanic who can properly diagnose and address the issue. Keep in mind that resolving lean codes may require addressing other potential causes as well.